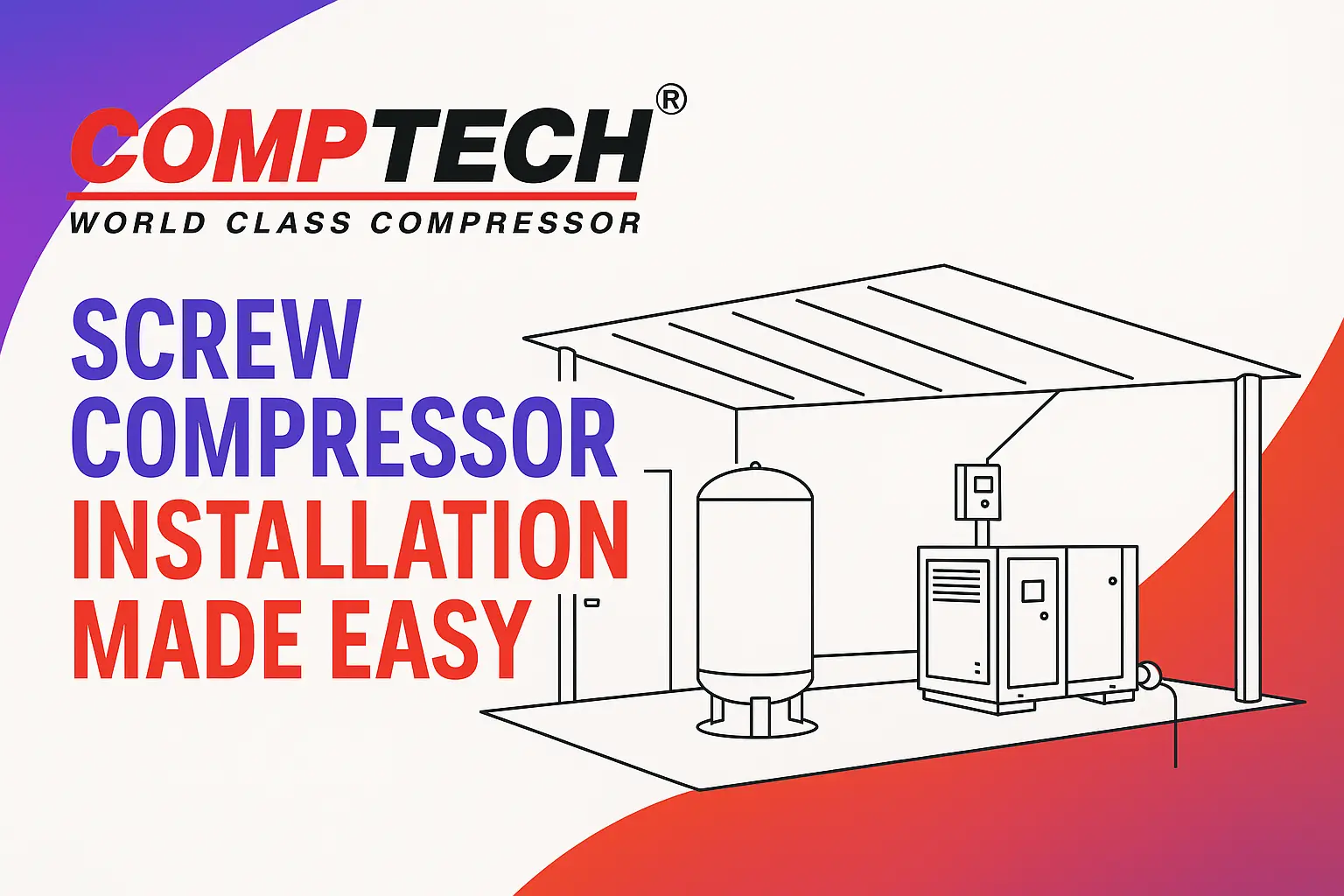

Easy Guide: How to Install New Screw Compressor Properly

How to Install Screw Compressor? Installing a screw air compressor in the right way is very important. If you don’t install it properly, the machine can overheat, stop working, make too much noise, or use extra electricity. So let’s learn how to do it right in a simple way.

1. Choose the Right Place for Installation

Where to keep the machine:

-

Keep the compressor in a clean, dry place, not in a dusty or wet area.

-

Try to keep it inside a room. If you must keep it outside, build a shed or cover to protect it from sun and rain.

Floor and base:

-

The compressor should be kept on a flat and strong concrete floor.

-

Put rubber pads or vibration pads under the machine to reduce shaking and sound.

Leave enough space:

-

Keep at least 1 meter (3 feet) of space around the compressor.

-

This space is needed to clean the machine, check oil, or do repairs.

-

Also leave some space at the top, in case you need to lift the machine later for service.

2. Electrical Setup, Airflow, and Safety

Electrical connection:

-

The machine should get the correct 3-phase power supply (like 415V).

-

Use thick wires as per the machine’s size.

-

Put proper switches, MCB, and safety relays.

-

Always connect earthing wire for safety.

-

In areas with power ups and downs, use a voltage stabilizer or surge protector.

Ventilation (air flow):

-

Compressors produce a lot of heat while running. So the room must have good airflow.

-

Put fans, windows, or ducts to remove hot air from the room.

-

Make sure cool and fresh air goes into the compressor.

-

Don’t let the hot air from the machine go back inside again.

Safety tips:

-

Keep a fire extinguisher near the compressor.

-

Paste emergency instructions on the wall (how to stop the machine quickly).

-

Test the emergency stop button to make sure it works.

-

Train your workers on how to use the machine safely.

3. Common Mistakes You Should Not Do

Wrong place:

-

Don’t keep the machine in a dirty or oily place — it can damage filters.

-

If there is no ventilation, the machine will become hot and stop working.

Wrong pipe size:

-

Don’t use small or thin air pipes. It will reduce air pressure.

-

Use the correct pipe size as told in the manual.

Using GI (Galvanized Iron) pipes:

-

These pipes rust from inside and send small iron pieces into your machines.

-

Use MS, aluminum, or SS pipes instead.

No vibration pads:

-

Don’t keep the compressor directly on the floor without rubber pads.

-

It will cause noise, shaking, and floor damage.

No drain line:

-

The compressor creates water (called condensate).

-

You must connect a drain pipe to remove this water safely.

No isolation valve:

-

Without a ball valve near the compressor, you cannot stop the air flow during service.

Poor electrical wiring:

-

Thin wires or loose connections can burn the motor or cause fire.

-

Always use proper wiring by an electrician.

Final Checklist Before You Start the Compressor

| Check This | Is It Done? |

|---|---|

| Concrete floor is flat and strong | |

| Enough space (1 meter) on all sides | |

| Correct electrical wire and connection | |

| Proper earthing and surge protector used | |

| Room has ventilation (fans or duct) | |

| Drain pipe connected properly | |

| Isolation valve installed | |

| Emergency stop tested |

Need Help?

We at Comptech Compressors are here to help you.

We provide:

-

Site visit and setup support

-

Room and wiring advice

-

Full installation and safety check

-

AMC (Annual Maintenance Contracts) and service

Call us today to install your compressor the right way from the start!

Leave A Comment